Basic QC Practices

Has your QC been Vanity-Sized?

Vanity sizing is a well known phenomenon in modern clothing lines, both for women and men. But does vanity-sizing stop at the clothes rack? Or have diagnostic manufacturers brought it into the laboratory?

Has your QC been "Vanity-sized"?

Sten Westgard

August 2013

For those of you with spouses, you know that clothes shopping has gotten increasingly complicated in recent years. This is because sizing is no longer standard - your spouse isn't just one size, he or she may be a variety of sizes, depending on the store and the clothes brand. The popular press has noted that a woman of a particular shape would have worn a size 14 dress in the Sear's catalog of 1937, but by 1967, she would have worn a size 8 dress, and today, she would wear a size 0 dress.[1] While this size "downshifting" is commonplace in women's sizes, it's just as rampant in men's clothing. Esquire's Abram Sauer tested the waist lines of men's pants from different brands - finding that sometimes a 36" waist on the label was actually as big as 41" in reality.[2]

Why is vanity sizing done? To appeal to consumers and make them feel better about themselves, and more importantly, more likely to buy the clothes they try on that "fit" them. As long as the sizing flatters the consumer's idea of what size they believe they should fit, and that results in more sales, vanity sizing is likely to continue in the clothing industry.

A little fudging of clothing sizes probably doesn't really hurt anyone. Maybe we're more productive if we think we're still able to wear pants and dresses that are same size we wore in our college days. But when it comes to the laboratory, the stakes are a little higher.

Does "Vanity-sizing" happen in the laboratory?

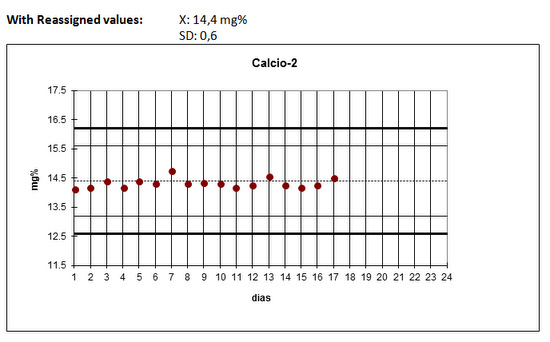

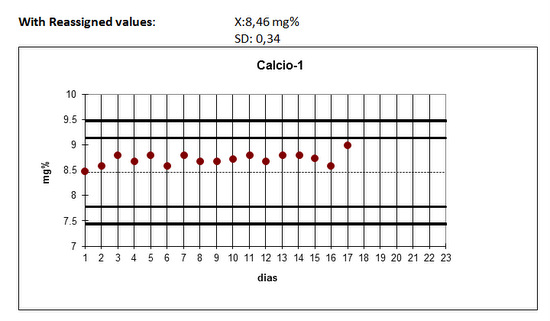

Here's a quick example of control charts built with a manufacturer's suggested SD. In this case, it's a calcium method, and the manufacturer sends out a notification to use a new SD when building control charts. The laboratory in this case is running two controls, high and low, and their language is Spanish:

With these reassigned SDs, we've got beautiful control charts, don't we? All the data is nice and tight, definitely within 2 SD limits (the high control looks like everything is within 1 SD of the mean, even). If this were your method, wouldn't you feel good about your quality?

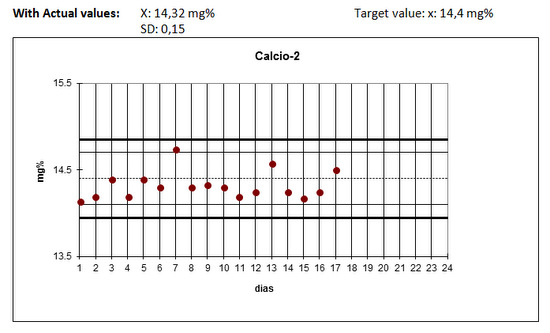

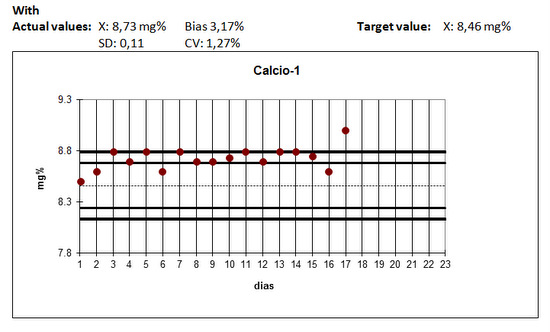

Now let's take a look at the same data with the laboratory's actual mean and SD:

Hmm. Not so good, right? That low control seems particularly troublesome. Remember, this is the same data. One set of graphs reflect the actual performance of the laboratory, but the other graphs show the "vanity sizing" recommended by the manufacturer.

The truth is, there is a lot of vanity-sized QC in labortories today. Manufacturers may recommend wider SDs and control limits through many ways: either by providing group SDs, enlarged "ranges", and outright recomendations for wide settings of control limits. Laboratories, on their part, might seek out their own vanity-sized QC by adopting peer group SDs, EQA or PT group SDs, or by simply pretending that a 3 SD range provided to them is really a 2 SD range. In all of these cases, it pushes the control limits out wider and potentially reduces the ability of the laboratory to detect a medically important error.

It's easy to understand the manufacturer's motivation. Just as the clothing manufacturer wants to place the consumer at ease. the manufacturer wants a happy laboratory. A happy laboratory doesn't call tech support, doesn't complain about drift and error, don't have to trouble-shoot, re-calibrate, or use more controls. A happy laboratory is a cheaper customer, because they don't demand more service and attention to address method problems. A happy laboratory gets a good feeling about a method, and attaches that good feeling to the whole instrument and manufacturer, perhaps, making it that much more likely to be a repeat customer, and purchase the next instrument.

Unfortunately, that happy laboratory is deluded. These widened control limits create a false sense of security. Worse still, this kind of vanity-sizing of control limits can present real dangers - it can mean that errors persist and grow unnoticed, until they finally reach a size that affects patient care. The lab may be happy, the manufacturer may be happy, but it's the patient who bears the brunt of this vanity.

To be fair, there are valid reasons to readjust control limits (or control means) on some occasions, particularly when done through data-driven techniques like Six Sigma QC Design. But if a manufacturer asks or recommends that you "loosen up" without giving you a reason, let the laboratory beware.

It's time to "right-size" our control limits. Not only might we trim the fat off some of our wasteful practices, we might also provide a better fit of our test results to the needs of our clinicians and patients.

References

- Stephanie Clifford, "One Size Fits Nobody: Seeking a Steady 4 or a 10", New York Times, April 24, 2011. http://www.nytimes.com/2011/04/25/business/25sizing.html?_r=0. Accessed 8/12/2013.

- Abram Sauer, "Are your pants lying to you? An investigation" Esquire, September 7, 2010. http://www.esquire.com/blogs/mens-fashion/pants-size-chart-090710 Accessed 8/12/2013.